Did you know that over 125 million workers worldwide face exposure to microscopic fibres daily? Asbestlint represents one of the most silent health threats present in buildings, homes, and industrial settings. These invisible particles float through the air without anyone noticing them.

Many people breathe contaminated air for years before symptoms appear. What makes these fibres so dangerous to human lungs? Medical research shows that even minimal contact can lead to serious respiratory conditions decades later.

This article explains how these harmful particles spread, where they hide, and what steps protect your family and workspace from long-term damage.

Table of Contents

What Asbestlint Is and How It Spreads

Are you aware of how airborne particles like Asbestlint might be present around you? These invisible threats exist in spaces where people work, live, and spend time daily without realising the danger surrounding them.

Definition of Asbestlint

Asbestlint refers to tiny airborne asbestos fibres that break away from building materials and float through indoor spaces. These particles measure less than 5 micrometres in diameter, making them completely invisible to the naked eye.

The term combines “asbestos” with “lint” because these fibres behave similarly to fabric dust. They remain suspended in the air for hours and settle on surfaces throughout rooms. Once disturbed, they become airborne again, creating continuous contamination cycles.

Airborne Asbestos Fibres and Their Movement

Toxic particle exposure happens through simple daily activities. When someone walks across old floor tiles or moves furniture against walls, microscopic fibre hazards are released into the breathing zones. Air currents from heating systems and open windows spread these particles throughout entire buildings.

Research from the Canadian Centre for Occupational Health and Safety indicates that a single fibre can split into hundreds of smaller pieces over time. This multiplication effect increases health risks significantly as buildings age.

Temperature changes cause building materials to expand and contract. This natural process gradually releases more fibre contamination into the surrounding air. Indoor pollution awareness becomes vital because these particles accumulate in carpets, ventilation ducts, and fabric furnishings.

Common Places Where Asbestlint Is Found

Construction sites rank as the highest risk areas for airborne contaminant prevention needs. Renovation projects disturb old materials and send thousands of particles into the air within minutes.

Industrial facilities built before 1980 contain extensive asbestos insulation around pipes, boilers, and machinery. Manufacturing plants processing mineral fibre produce continuous environmental health risks for workers on production floors.

Schools and public buildings with ageing infrastructure harbour hidden air quality threats. Ceiling tiles, floor coverings, and wall panels in these structures slowly deteriorate and release harmful particles into classrooms and offices.

Everyday Places Where Asbestlint Can Appear

Your home might contain these hazardous fibres with obvious warning signs. Older popcorn ceilings, vinyl floor tiles, and exterior siding materials often include asbestos composition. Attic insulation in houses built before 1990 frequently contains these dangerous minerals.

Garages and workshops present additional exposure points. Automotive brake pads, clutch assemblies, and gasket materials historically used asbestos for heat resistance. Home mechanics working with older vehicle parts face fibre inhalation dangers during routine maintenance.

Garden sheds and outbuildings with corrugated roofing sheets pose outdoor risks. Rain and wind erosion gradually break down these materials, spreading contamination across properties.

Why People Often Overlook Microscopic Fibres

Visual inspection alone cannot detect Asbestlint presence. These particles require electron microscopy for identification, which costs between $400-$800 per sample according to EPA testing standards. Many property owners skip professional testing due to expense concerns.

Symptoms from toxic particle exposure take 10-40 years to develop. This delayed reaction creates false security among people living in contaminated environments. By the time health problems appear, significant lung damage has already occurred.

Building material labels rarely mention asbestos content clearly. Manufacturers used vague terms like “mineral fibre” or “composite material” on product specifications, hiding actual composition from consumers and contractors.

Why Asbestlint Affects Our Health

Understanding how these microscopic particles damage your body helps you protect yourself and your loved ones. Medical evidence shows that even limited contact creates lasting health consequences that appear years later.

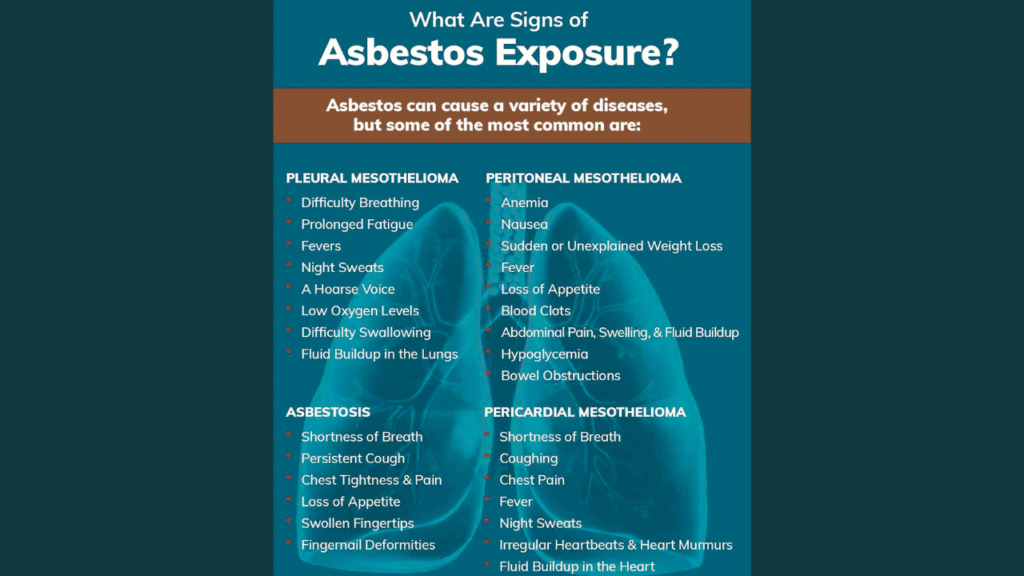

Early Signs of Asbestlint

Respiratory health threats begin with subtle symptoms that people often mistake for common allergies or ageing. Persistent dry cough lasting more than three weeks serves as an initial warning sign of fibre contamination exposure.

Shortness of breath during light physical activity indicates potential lung tissue damage. Chest tightness and unusual fatigue accompany these breathing difficulties as microscopic fibres lodge in lung structures.

Fingertip clubbing, where fingernails curve downward abnormally, signals advanced respiratory compromise. Medical professionals recognise this physical change as a marker for serious lung disease risk from prolonged particle inhalation.

Lung Disease From Fibre Inhalation Dangers

Asbestosis develops when lung tissue becomes scarred from continuous fibre exposure. The World Health Organisation reports that approximately 107,000 workers die annually from asbestos-related diseases. This irreversible condition progressively reduces lung capacity and oxygen absorption.

Pleural plaques form on the lung lining as the body attempts to isolate foreign particles. These calcified deposits restrict lung expansion and cause chronic pain during breathing. Medical scans reveal these formations in 50% of workers with 20+ years of industrial exposure.

Chronic obstructive pulmonary disease (COPD) acceleration occurs when Asbestlint combines with smoking or other respiratory irritants. Patients experience a rapid decline in breathing function compared to standard COPD progression rates.

Mesothelioma and Other Illnesses Linked to Exposure

Mesothelioma causes a particularly aggressive cancer affecting the thin tissue layer covering internal organs. This rare disease has a 90% correlation with asbestos exposure, according to the American Cancer Society. Survival rates remain low, with only 10% of patients living beyond five years after diagnosis.

Lung cancer risk increases fivefold among exposed individuals who smoke. The cancer-causing dust acts as a catalyst that multiplies tobacco’s carcinogenic effects on cellular DNA. Non-smokers with heavy exposure face double the normal lung cancer rates.

Laryngeal and ovarian cancers show statistical links to long-term fibre contamination. Studies published in medical journals document these connections through occupational health data spanning decades.

How Tiny Fibres Cause Long-Term Damage

Each microscopic fibre acts like a tiny needle penetrating deep into the lung tissue. The immune system cannot break down these mineral particles, so they remain embedded permanently. White blood cells surround the fibres, creating inflammation that damages the surrounding tissue.

Cell mutation occurs when fibres disrupt normal cell division processes. DNA replication errors accumulate over years of persistent inflammation. This biological damage eventually triggers uncontrolled cell growth and tumour formation.

Scarring develops as the body deposits collagen around embedded fibres. This fibrous tissue stiffens lung structures and reduces their elasticity. Breathing becomes progressively more difficult as scarred areas replace functional lung tissue.

Everyday Sources of Asbestlint in Buildings

Buildings constructed decades ago contain hidden dangers that most people never think about. Knowing where these hazardous fibres hide helps you take protective action before exposure occurs.

Fibre Cement Boards and Building Material Safety

Fibre cement boards manufactured before 2000 commonly contained 10-50% asbestos content. These boards served as siding, roofing underlayment, and interior wall panels in millions of structures. Construction material hazards persist as these products age and deteriorate.

Modern fibre cement boards use safer cellulose fibres and synthetic materials. However, distinguishing old from new boards requires laboratory testing. Visual similarity between asbestos and non-asbestos versions creates identification problems during renovation projects.

Exterior cladding on commercial buildings represents massive contamination sources. Weather exposure causes surface erosion that releases particles into the surrounding air and soil. Rain runoff carries these fibres into drainage systems and groundwater supplies.

Old Homes and Construction Material Safety

Houses built between 1920-1980 contain the highest asbestos concentrations. Insulation wrapping around heating ducts, pipes, and furnaces typically uses this mineral for fire protection. Wall and ceiling texture compounds applied during this period often included asbestos fibres for strength.

Window glazing putty and caulking materials hardened with asbestos additives. These sealants become brittle over time and crumble when windows are opened or closed. Homeowners performing DIY repairs unknowingly create airborne contaminant situations.

Linoleum flooring backing and adhesives present hidden risks beneath newer floor coverings. Removal or sanding of old flooring releases accumulated particles that have settled in material layers over decades.

Industrial Air Contamination in Workplaces

Manufacturing facilities face the most severe workplace safety standards challenges. Textile mills, shipyards, and automotive plants historically used asbestos in production processes. Ventilation systems in these buildings circulate contaminated air throughout workspaces.

Power plants and refineries installed extensive pipe insulation containing high asbestos percentages. Maintenance activities disturbing this insulation create acute exposure incidents affecting entire work crews. Occupational health protection requires strict protocols during any insulation work.

Mining operations and mineral processing facilities generate environmental asbestos cleanup demands. Ore crushing and grinding operations produce dust clouds containing natural asbestos from geological formations.

Indoor Pollution Awareness and Hidden Air Quality Threats

Office buildings with suspended ceiling systems harbour accumulated fibre deposits. Air handling systems draw particles from ceiling voids and distribute them through occupied spaces. HVAC filters capture some particles, but microscopic fibres pass through standard filtration media.

Parking garages beneath buildings concentrate vehicle brake dust containing asbestos residue. These enclosed spaces lack adequate ventilation, allowing particles to drift into stairwells and elevators serving upper floors.

Apartment complexes share contamination between units through common walls and ductwork. A single renovation project in one unit can expose residents throughout the building to hazardous material control violations.

Table: Comparison of Asbestlint Presence and Safety Measures

| Aspect | Common Source | Safety Measure | Impact |

| Fibre Cement Boards | Old building materials | Use friendly alternatives | Reduces fibre inhalation dangers |

| Industrial Air Contamination | Factories using asbestos | Regular airborne dust monitoring | Limits toxic particle exposure |

| Indoor Pollution | Poor ventilation in homes/offices | High-efficiency air filtration systems | Protects against microscopic fibres |

| Construction Sites | Renovation of old structures | Protective equipment for asbestos | Prevents respiratory health threats |

| Workplace Environments | Manufacturing plants | Strict workplace safety standards | Reduces lung disease risk |

How to Spot Asbestlint in Your Surroundings

Detecting invisible particles requires specific testing methods and awareness of warning signs. Professional assessment combined with visual inspection provides the best protection against unnoticed contamination.

Fibre Contamination Detection and Asbestos Testing Methods

Professional testing requires collecting samples from suspected materials using specialised equipment. Polarised light microscopy (PLM) identifies fibre types with 99% accuracy according to EPA Method 600. Laboratories charge $50-$75 per sample for this analysis.

Transmission electron microscopy (TEM) detects smaller particles than the PLM method. This advanced testing costs $150-$200 per sample but provides definitive identification of microscopic fibre hazards. Industrial hygienists recommend TEM for air quality verification after abatement projects.

Bulk material sampling involves carefully cutting small pieces from suspected products. Wetting the area before sampling prevents fibre release during collection. Samples must be sealed in airtight containers and labelled with location details.

Airborne Dust Monitoring and Testing Approaches

Air monitoring uses specialised pumps that draw measured volumes through collection filters. These pumps operate for 4-8 hours to capture representative samples of breathing zone conditions. Phase contrast microscopy (PCM) counts total fibres in air samples.

Real-time monitors using laser technology detect particle concentrations instantly. These devices cost $5,000-$15,000 but provide immediate feedback during abatement activities. Construction site safety protocols increasingly require continuous monitoring.

Personal air sampling involves workers wearing small pumps attached to breathing zones. This method documents actual exposure levels that individuals receive during work shifts. OSHA regulations mandate this monitoring when airborne particles exceed 0.1 fibres per cubic centimetre.

Signs of Asbestos Contamination to Watch For

Visible material deterioration serves as the primary warning indicator. Crumbling insulation, cracked floor tiles, and damaged ceiling panels all suggest potential fibre release. Water damage accelerates breakdown and increases particle generation.

Dusty surfaces that reappear quickly after cleaning indicate ongoing particle settling. Persistent dust on horizontal surfaces often contains fibre contamination in older buildings. HVAC vent covers with heavy dust accumulation show circulation of contaminated air.

Musty odours combined with dust presence suggest hidden moisture problems. Water intrusion damages asbestos materials faster than dry conditions. Basement and crawl space inspections should check for damp insulation and pipe wrapping.

Public Health Precautions Through Workplace Safety Standards

OSHA permissible exposure limit (PEL) stands at 0.1 fibres per cubic centimetre averaged over 8-hour shifts. Excursion limits allow 1.0 fibre per cubic centimetre for 30-minute periods. Employers must implement controls when monitoring shows these thresholds exceeded.

Medical surveillance programs require chest X-rays and pulmonary function tests for exposed workers. Annual health screenings detect early lung disease risk before symptoms develop. Workers receive baseline examinations before starting jobs involving potential exposure.

Training programs must teach hazardous material control procedures to all affected employees. Competent person certification ensures that qualified supervisors oversee work activities. Documentation requirements track training completion and exposure incidents.

Expert Quote on Health Risks

“Even tiny asbestos fibres in the air can cause life-changing health issues. Awareness and proper handling of Asbestlint can save lives.” Environmental Health Researcher

This statement reflects decades of medical research showing that prevention through education and proper procedures remains the only effective defence against these microscopic hazards.

Inspiring Example of School Safety Success

A school undergoing renovation found hidden asbestos in the ceiling tiles. The maintenance team noticed deteriorating material during a routine inspection before starting the project. They immediately stopped all work and called licensed testing professionals.

Laboratory analysis confirmed high asbestos content in the tiles. Because of timely fibre contamination detection and safe removal, the building avoided a serious indoor pollution issue that could have affected hundreds of children. The school district spent $45,000 on professional abatement, but prevented potential health problems worth millions in future medical costs and legal liability.

The project took three weeks with proper containment and disposal. Students and teachers returned to a completely safe environment, with air quality testing confirming zero contamination. This example shows how awareness and quick action protect communities from long-term exposure to dangers.

Handling to Manage and Remove Asbestlint Safely

Proper removal techniques protect workers and building occupants from dangerous exposure incidents. Following established procedures makes the difference between safe cleanup and creating worse contamination problems.

Protective Equipment for Asbestos Handling

Respirators with HEPA filtration provide the minimum acceptable protection during fibre exposure activities. Half-face respirators work for short-duration tasks, while full-face models suit extended work periods. Fit testing ensures a proper seal between the mask and skin.

Disposable coveralls with attached hoods prevent particle contamination of clothing and skin. Tyvek suits cost $8-$15 each and must be discarded after single use. Duct tape seals suit openings at wrists, ankles, and hood edges.

Glove selection depends on work type and chemical exposures present. Nitrile gloves resist tears better than latex when handling rough materials. Double gloving provides backup protection if outer gloves rip during work.

Safe Asbestos Removal and Abatement Process

Professional abatement contractors must hold state licenses and maintain liability insurance covering asbestos work. Proper abatement for a typical home costs $15,000-$30,000, depending on contamination extent. Commercial projects run $50-$200 per square foot.

Containment barriers isolate work areas from occupied spaces. Plastic sheeting creates airtight enclosures with negative air pressure systems drawing air inward. HEPA-filtered exhaust prevents particle escape to outside areas.

Wet methods keep materials saturated throughout removal processes. Water mixed with surfactant solutions penetrates materials and binds fibres. Workers apply amended water continuously using low-pressure sprayers.

Avoiding Environmental Asbestos Cleanup Errors

Never dry sweep or vacuum asbestos materials with standard equipment. Regular vacuum cleaners exhaust particles back into the air through motor cooling vents. Only HEPA-filtered vacuums rated for asbestos work provide adequate capture.

Pressure washing exterior materials spreads contamination across properties. High-pressure streams fragment materials and create airborne clouds, affecting neighbours. Hand scraping with wetting produces less particle generation.

Improper disposal causes environmental contamination when materials reach standard landfills. Double-bagging in 6-mil polyethene bags with proper labelling meets transport requirements. Specialised disposal facilities charge $80-$150 per ton for asbestos waste.

Wet Cleaning Methods to Reduce Airborne Particles

Misting systems maintain high humidity levels during abatement activities. Fine water droplets settle particles before they become airborne. Automatic misting runs continuously throughout work shifts.

HEPA vacuuming removes settled particles from surfaces after material removal. Vacuum heads must contact surfaces gently to avoid creating new airborne particles. Multiple passes ensure complete particle capture.

Damp wiping with disposable cloths removes residual contamination from surfaces. Workers wipe in one direction and fold cloths to expose clean surfaces. Used cloths become asbestos waste requiring proper disposal.

Essential Safety Practices Checklist

Before Starting Any Work:

- Always test suspicious materials before disturbing them

- Hire certified professionals for testing and removal

- Verify contractor licenses and insurance coverage

- Create written work plans detailing all safety procedures

During Removal Activities:

- Maintain wet conditions on all materials being handled

- Keep work areas sealed with negative air pressure

- Wear proper respiratory protection at all times

- Monitor air quality continuously throughout the project

After Completion:

- Conduct clearance air testing before reoccupying spaces

- Dispose of all contaminated materials at approved facilities

- Document all activities with photos and written records

- Store safety documentation for future reference

Safer Alternatives to Asbestlint in Industry

Modern materials provide equal or better performance without the health risks associated with asbestos. Industry advances over recent decades have created effective replacements for every traditional asbestos application.

Fibre Cement Boards and Eco-Friendly Safety Solutions

Modern fibre cement products use cellulose fibres from recycled paper and wood. These boards provide similar strength and fire resistance without health risks. Market prices remain competitive with historical asbestos products.

Manufacturers offer 50-year warranties on new fibre cement siding. These products resist rot, insects, and fire while maintaining stable dimensions through weather changes. Installation methods mirror traditional asbestos board techniques.

Green building certifications recognise non-asbestos fibre cement as a sustainable material. LEED projects earn credits for using these safer alternatives. Environmental product declarations document reduced manufacturing impacts.

You Might Also Like: HMS Photovoltaik

Building Material Safety Through Modern Replacements

Spray-applied cellulose insulation replaces loose asbestos insulation in attics and walls. This material provides superior R-values while using recycled newspaper content. Installation costs run $1.50-$2.50 per square foot.

Mineral wool batts offer fire-resistant insulation without asbestos content. These products withstand temperatures exceeding 2,000°F while maintaining structural integrity. Sound-dampening properties exceed fibreglass insulation performance.

Calcium silicate boards serve high-temperature applications previously requiring asbestos millboard. Industrial furnaces and kilns use these boards for lining and insulation. Performance matches or exceeds asbestos products at comparable costs.

Air Purity and Filtration for Sustainable Environmental Safety

HEPA filtration systems remove 99.97% of particles 0.3 micrometres or larger. Whole-building filtration upgrades cost $2,000-$5,000 for residential applications. Commercial installations require professional design for proper air handling.

Activated carbon filters complement HEPA systems by removing chemical contaminants. Combined filtration addresses both particulate and gaseous pollutants. Filter replacement schedules depend on contamination levels and system usage.

UV-C germicidal lights integrated with HVAC systems provide additional air treatment. These lights destroy biological contaminants passing through ductwork. Energy consumption adds minimal cost to operating expenses.

Rules for Keeping Workers and the Public Safe

Government regulations establish minimum protection standards that employers must follow. Compliance with these rules prevents exposure incidents and protects vulnerable populations from contamination.

Workplace Safety Standards on Hazardous Material Control

OSHA Construction Standard 1926.1101 governs asbestos work activities. This regulation requires employers to assess potential exposure before starting projects. Written compliance programs document control measures and training.

Regulated areas restrict access to authorised personnel wearing proper protection. Warning signs display required text in languages understood by affected workers. Barriers prevent unauthorised entry to contaminated zones.

Shower facilities and change rooms separate contaminated work clothing from street clothes. Workers must shower before leaving work sites when exposure exceeds PEL values. Contaminated clothing laundering requires specialised services.

Occupational Health Protection Practices

Medical examinations include detailed work history questionnaires documenting all asbestos exposures. Physicians certified in pulmonary medicine interpret results and provide recommendations. Workers receive copies of all medical findings.

Pulmonary function tests measure lung capacity and airflow restrictions. Spirometry testing takes 15-20 minutes and provides baseline values for comparison. Declining values trigger additional medical evaluation.

Chest X-rays follow the ILO classification system for pneumoconiosis interpretation. Board-certified radiologists trained in B-reading evaluate films for asbestos-related changes. Digital imaging improves the detection of subtle abnormalities.

Legal Considerations and Public Health Precautions

Property owners face liability for exposing occupants to asbestos hazards. Disclosure laws require sellers to inform buyers about known contamination. Failure to disclose creates grounds for legal action and financial damages.

Contractor licensing requirements vary by state, but generally mandate specialised training. Unlicensed asbestos work results in fines ranging from $5,000-$25,000 per violation. Criminal penalties apply for serious safety violations.

Insurance policies often exclude asbestos-related claims unless specific coverage exists. Pollution liability insurance costs $2,000-$10,000 annually, depending on risk factors. Some insurers refuse coverage for properties with known contamination.

Quick Safety Tips

- Never disturb suspected asbestos materials without a professional assessment.

- Wet surfaces before any contact with old building materials

- Keep children away from deteriorating materials in older homes

- Hire licensed professionals for any asbestos removal projects

- Ventilate spaces thoroughly after completing renovation work

- Document everything, including material locations and testing results

Modern Steps to Keep Air Clean and Safe

Technology and better understanding create new ways to maintain healthy indoor environments. Combining traditional methods with modern innovations produces the most effective protection strategies.

Air Purity and Filtration Strategies

Regular filter replacement maintains system effectiveness and prevents particle buildup in ductwork. Residential systems need filter changes every 1-3 months, depending on contamination levels. Commercial buildings require monthly inspections.

Duct cleaning removes accumulated particles from ventilation systems. Professional cleaning costs $450-$1,000 for average homes. This service becomes necessary every 3-5 years or after renovation projects.

Portable air purifiers supplement central systems in high-risk areas. Units sized for room volume process air multiple times hourly. CADR ratings indicate cleaning speed for different particle sizes.

Sustainable Environmental Safety Approaches

Source control prevents contamination rather than treating symptoms. Encapsulation products seal deteriorating materials and prevent fibre release. Coating costs $2-$5 per square foot for professional application.

Green remediation strategies minimise environmental impact during cleanup activities. These methods reduce waste volume and energy consumption. Life cycle analysis demonstrates lower carbon footprints compared to traditional approaches.

Continuous improvement programs review safety data and update procedures regularly. Lessons learned from incidents inform better practices across industries. Sharing information prevents others from repeating mistakes.

Eco-Friendly Safety Solutions for Homes and Industries

Smart building technologies monitor air quality continuously and alert occupants to contamination events. Sensors detect particle concentrations and trigger ventilation adjustments. Integration with building automation optimises energy while maintaining safety.

Natural ventilation strategies reduce reliance on mechanical systems. Operable windows and passive air flow dilute contaminants without energy consumption. Design considerations balance indoor air quality with thermal comfort.

Plant-based air cleaning uses specific vegetation to remove airborne pollutants. NASA research identified plants effective at particle capture. While not replacing mechanical filtration, plants provide supplementary benefits.

Preventing Future Exposure

Pre-purchase inspections identify asbestos hazards before property transactions. Specialised inspectors charge $400-$800 for comprehensive building surveys. Inspection reports guide negotiation and renovation planning.

Renovation planning must include asbestos surveys before any demolition. Disturbing unknown materials creates uncontrolled exposure affecting workers and occupants. Professional surveys cost less than emergency abatement after accidental release.

Product selection focuses on certified asbestos-free materials. Third-party testing verifies manufacturer claims about material composition. Documentation proves compliance with regulations and standards.

Key Prevention Strategies

For Homeowners:

- Schedule professional inspections before buying older properties

- Never attempt DIY removal of suspected asbestos materials

- Keep detailed records of all testing and abatement work

- Educate family members about material locations and risks

- Maintain adequate ventilation throughout living spaces

For Employers:

- Implement comprehensive worker training programs annually

- Provide appropriate protective equipment at no cost

- Conduct regular air monitoring in high-risk areas

- Maintain current licenses and certifications

- Create emergency response plans for accidental releases

For Building Managers:

- Develop asbestos management plans for all properties

- Perform annual visual inspections of known materials

- Coordinate safe work practices across all contractors

- Keep occupants informed about material locations

- Budget for eventual removal or encapsulation projects

Asbestlint Awareness for Safer Living

Taking action now prevents health problems that could affect you and your family for decades. The small investment in testing and proper management pays enormous dividends in protected health and peace of mind.

Environmental Health Risks if Asbestlint Is Ignored

Delayed action on contamination leads to widespread exposure affecting entire communities. Property values decline when asbestos presence becomes public knowledge. Cleanup costs escalate as contamination spreads through neglect.

Health care expenses from asbestos diseases burden individuals and healthcare systems. Treatment for mesothelioma averages $400,000-$800,000 over a patient’s remaining lifetime. Prevention costs a fraction of disease treatment expenses.

Legal liabilities persist for decades after initial exposure occurs. The statute of limitations begins when diseases manifest, not when the exposure happened. This creates long-term financial risks for property owners and employers.

Airborne Contaminant Prevention Through Strict Monitoring

Regular air quality testing documents building safety and provides early warning of problems. Testing frequencies depend on building age, condition, and occupancy type. Schools and healthcare facilities require more frequent monitoring.

Maintenance programs address deteriorating materials before they release significant particle quantities. Proactive repairs cost less than emergency responses to contamination incidents. Budgeting for ongoing maintenance prevents deferred problems.

Staff training creates a vigilant workforce that recognises potential hazards. Employees report concerns before situations become serious. Safety culture development requires consistent management commitment and resource allocation.

Importance of Ongoing Asbestos Management

Management plans document material locations and condition assessments. Annual inspections update information and track deterioration rates. Plans guide decisions about repair, encapsulation, or removal timing.

Operations and maintenance procedures protect materials from damage during routine activities. Work practices minimise disturbance to asbestos-containing materials. Contractor coordination ensures all workers understand restrictions.

Communication plans inform occupants about asbestos presence and management strategies. Transparency builds trust and encourages reporting of damaged materials. Information sharing prevents rumours and misinformation.

Encouraging Safer Air Awareness for Health Protection

Public education campaigns raise awareness about microscopic fibre hazards in communities. Local health departments provide resources for homeowners and small businesses. Free testing programs help identify properties needing attention.

Advocacy groups push for stronger regulations and better enforcement. Grassroots organisations represent affected individuals in policy discussions. Political pressure drives legislative improvements.

Technology development continues to improve detection and removal methods. Research investments produce safer, more effective solutions. Industry collaboration accelerates the adoption of best practices.

Comparison Table: Asbestos Testing Methods

| Testing Method | Detection Range | Accuracy Rate | Cost Per Sample | Processing Time |

| Polarised Light Microscopy (PLM) | >1 micrometre | 99% | $50-$75 | 2-3 days |

| Transmission Electron Microscopy (TEM) | >0.01 micrometres | 99.9% | $150-$200 | 5-7 days |

| Phase Contrast Microscopy (PCM) | >0.25 micrometres | 95% | $25-$40 | 1-2 days |

Source: EPA Method 600 Standards & Laboratory Testing Guidelines

Expert Quote According to Dr Richard Lemen, former Assistant Surgeon General: “There is no safe level of asbestos exposure. Even brief encounters with airborne fibres can initiate disease processes that manifest decades later. Prevention through identification and proper management remains our only effective strategy.”

Increasing Awareness About Asbestlint for Healthier Air and Life

Ignoring the environmental health effects connected to Asbestlint can lead to serious breathing problems and other long-term illnesses. Careful airborne dust monitoring and continued asbestos management play a key role in guarding against this quiet but harmful presence. Raising awareness about safer air helps communities and workplaces stay alert to occupational health protection needs and building material safety standards.

Regular inspections and air quality checks reduce asbestos contamination and prevent fiber inhalation dangers before they grow worse. Safer air is possible when everyone takes part in understanding safe handling and cleanup of this hidden hazard. Taking steps now supports healthier living and promotes public health precautions for future generations.